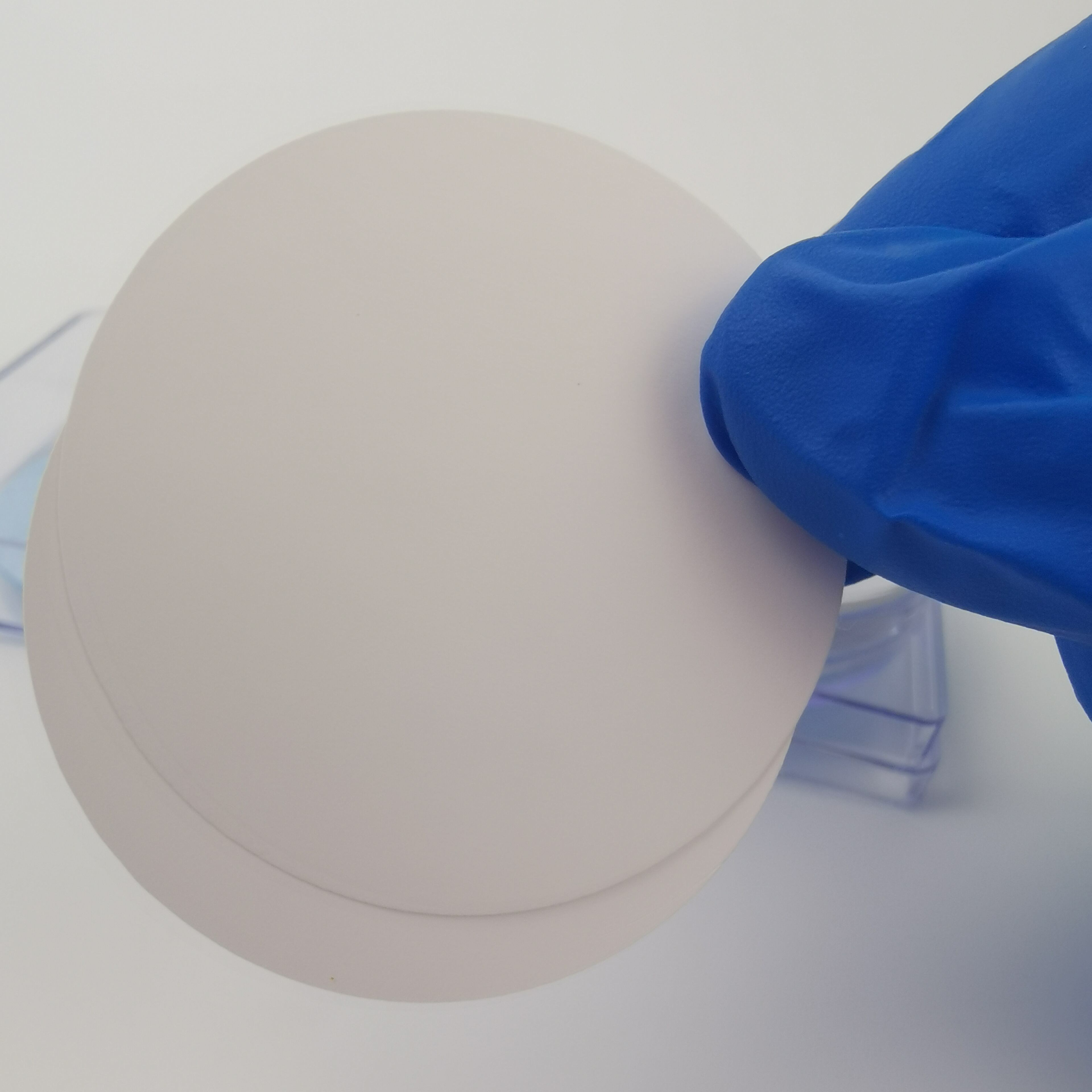

ავტოკლავირებადი სინჯის ფილტრი

Ავტოკლავის შესაძლებლობით მოცურავი საწვეტი ფილტრები წარმოადგენენ ლაბორატორიული ფილტრაციის ტექნოლოგიაში მნიშვნელოვან პროგრესს, რადგან ისინი აერთიანებენ ხანგრძლივობას და სიზუსტეს სამეცნიერო გამოყენებაში. ეს სპეციალური ფილტრები შექმნილია იმაზე, რომ გაუძლონ მაღალი წნევის მქონე რძის სტერილიზაციას და შეინარჩუნონ მათი სტრუქტურული მთლიანობა და ფილტრაციის ეფექტურობა. ფილტრების კორპუსი საჭიროებს მაღალხარისხოვანი თერმოპლასტმასებისგან დამზადებულ მასალებს, რომლებიც შეძლებენ გაუძლონ ტემპერატურას 121°C-მდე ავტოკლავირების პროცესში. მათი დიზაინი მოიცავს რამდენიმე ფენას მემბრანული ფილტრაციის მასალისგან, რაც უზრუნველყოფს ნაწილაკების, მიკროორგანიზმების და სხვა დამაბინძურებელი ნივთიერებების ეფექტურ ამოღებას სითხის საცდელი ნიმუშებიდან. ფილტრები ხელმისაწვდომია სხვადასხვა ნახვრების ზომებით, რომლებიც მერყეობს 0.22-დან 0.45 მიკრონამდე, რაც ხდის მათ შესაფერისს სხვადასხვა ფილტრაციის მოთხოვნებისთვის. მნიშვნელოვანი მახასიათებელია მათი მრავალჯერადად გამოყენების შესაძლებლობა სტერილიზაციის შემდეგ, რაც იძლევა როგორც ეკონომიკურ, ასევე გარემოს დაცვის სარგებელს. ფილტრები აღჭურვილია სტანდარტული ლუერ ბლოკირების კავშირებით, რაც უზრუნველყოფს თითქმის ყველა ლაბორატორიული საწვეტისთვის შესაბამისობას და გამოყენების მარტივობას. მათი კონსტრუქცია მოიცავს წნევამედეგ დანადგარებს და გამაგრებული მემბრანის მხარდამჭერ სტრუქტურებს, რაც აცილებს საცდელი ნიმუშის დაკარგვას და უზრუნველყოფს მუდმივ შესრულებას სტერილიზაციის მრავალ ციკლზე განკუთვნილი პროცედურების განმავლობაში.