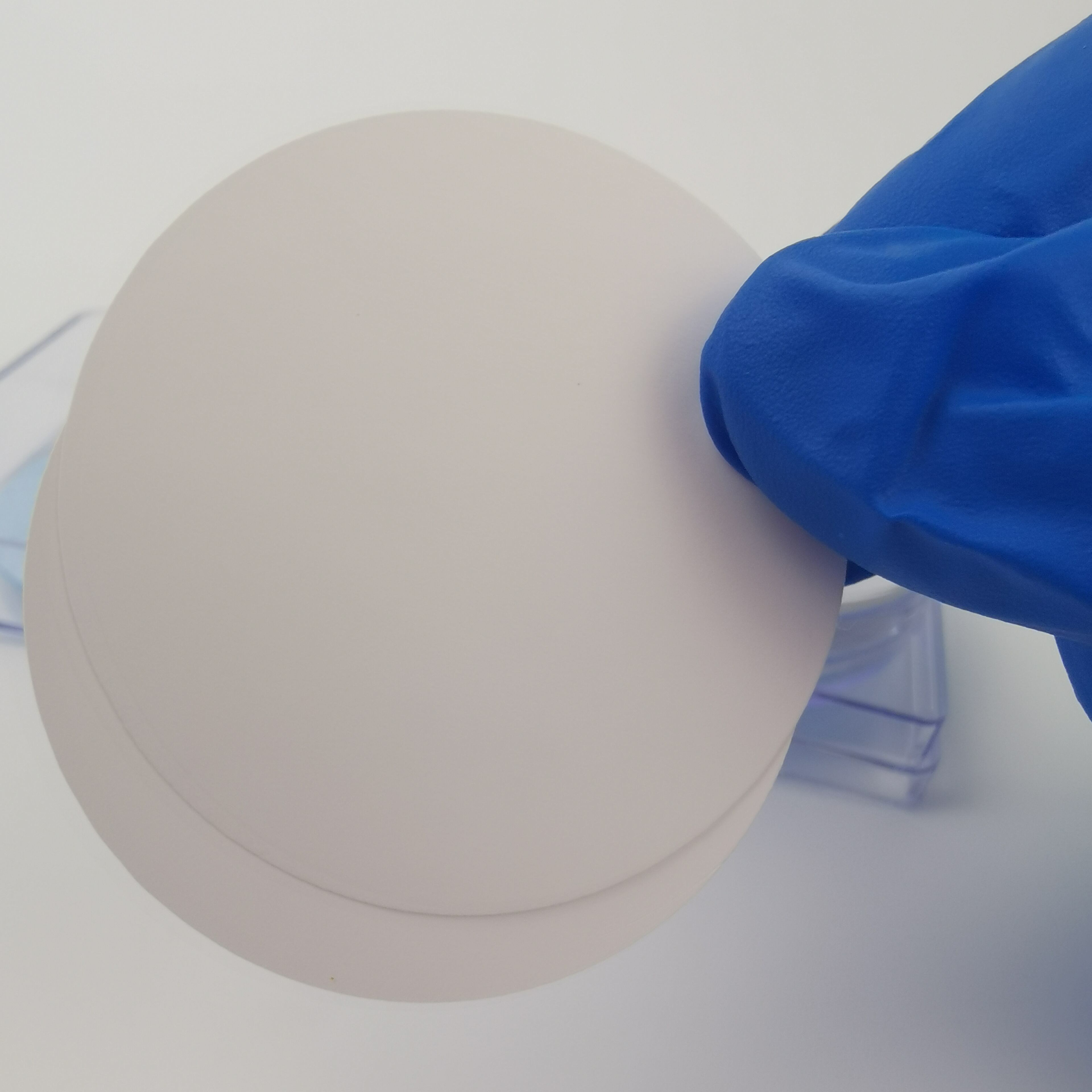

autoclavable syringe filter

Autoclavable syringe filters represent a crucial advancement in laboratory filtration technology, combining durability with precision in scientific applications. These specialized filters are engineered to withstand high-pressure steam sterilization while maintaining their structural integrity and filtration efficiency. The filters feature a robust housing typically constructed from high-grade thermoplastic materials, capable of enduring temperatures up to 121°C during the autoclaving process. Their design incorporates multiple layers of membrane filtration media, ensuring effective removal of particulates, microorganisms, and other contaminants from liquid samples. The filters are available in various pore sizes, ranging from 0.22 to 0.45 microns, making them suitable for different filtration requirements. A key characteristic is their ability to be reused multiple times after proper sterilization, offering both economic and environmental benefits. These filters are equipped with standard luer lock connections, ensuring compatibility with most laboratory syringes and facilitating ease of use. The construction includes pressure-resistant seals and reinforced membrane support structures, preventing sample loss and ensuring consistent performance through multiple sterilization cycles.