Understanding the Core Elements of HPLC Column Performance

High-performance liquid chromatography (HPLC) has revolutionized analytical chemistry, with column efficiency standing as the cornerstone of successful separations. The intricate relationship between various operational parameters and HPLC column efficiency determines the quality of analytical results. Whether you're a seasoned chromatographer or new to the field, mastering these factors is crucial for achieving optimal separation performance.

The science behind HPLC column efficiency involves complex interactions between the mobile phase, stationary phase, and analytes. When these elements work in harmony, they produce sharp, well-resolved peaks that enable accurate quantification and identification of compounds. However, even minor variations in operating conditions can significantly impact separation quality.

Mobile Phase Parameters and Their Impact

Flow Rate Optimization

The mobile phase flow rate directly influences HPLC column efficiency through its effect on mass transfer and diffusion processes. Too high a flow rate can lead to band broadening and decreased resolution, while too slow a flow may result in excessive analysis times and peak diffusion. Finding the optimal flow rate requires careful consideration of the column dimensions, particle size, and analyte properties.

Modern HPLC systems allow precise control over flow rates, typically ranging from 0.1 to 2.0 mL/min for standard analytical columns. The van Deemter curve serves as a valuable tool for determining the optimal flow rate, where the minimum plate height represents the best compromise between various band-broadening effects.

Solvent Composition Effects

The composition of the mobile phase significantly affects HPLC column efficiency through its influence on selectivity and retention. Proper selection of organic modifiers, pH adjusters, and buffer components can dramatically improve peak shape and resolution. The solvent's viscosity and surface tension also play crucial roles in determining the overall separation efficiency.

When optimizing solvent composition, consider the chemical properties of both the analytes and the stationary phase. Matching solvent strength to the separation requirements helps achieve optimal retention times while maintaining peak shape integrity.

Physical and Chemical Properties of the Column

Particle Size and Morphology

The size and shape of stationary phase particles fundamentally affect HPLC column efficiency. Smaller particles generally provide better efficiency due to reduced diffusion paths and improved mass transfer kinetics. Modern columns often utilize sub-2-μm particles to achieve superior separation performance, though this comes with increased backpressure requirements.

Particle morphology, whether fully porous or superficially porous, influences the column's loading capacity and separation speed. Core-shell particles have gained popularity for their ability to provide excellent efficiency while maintaining reasonable operating pressures.

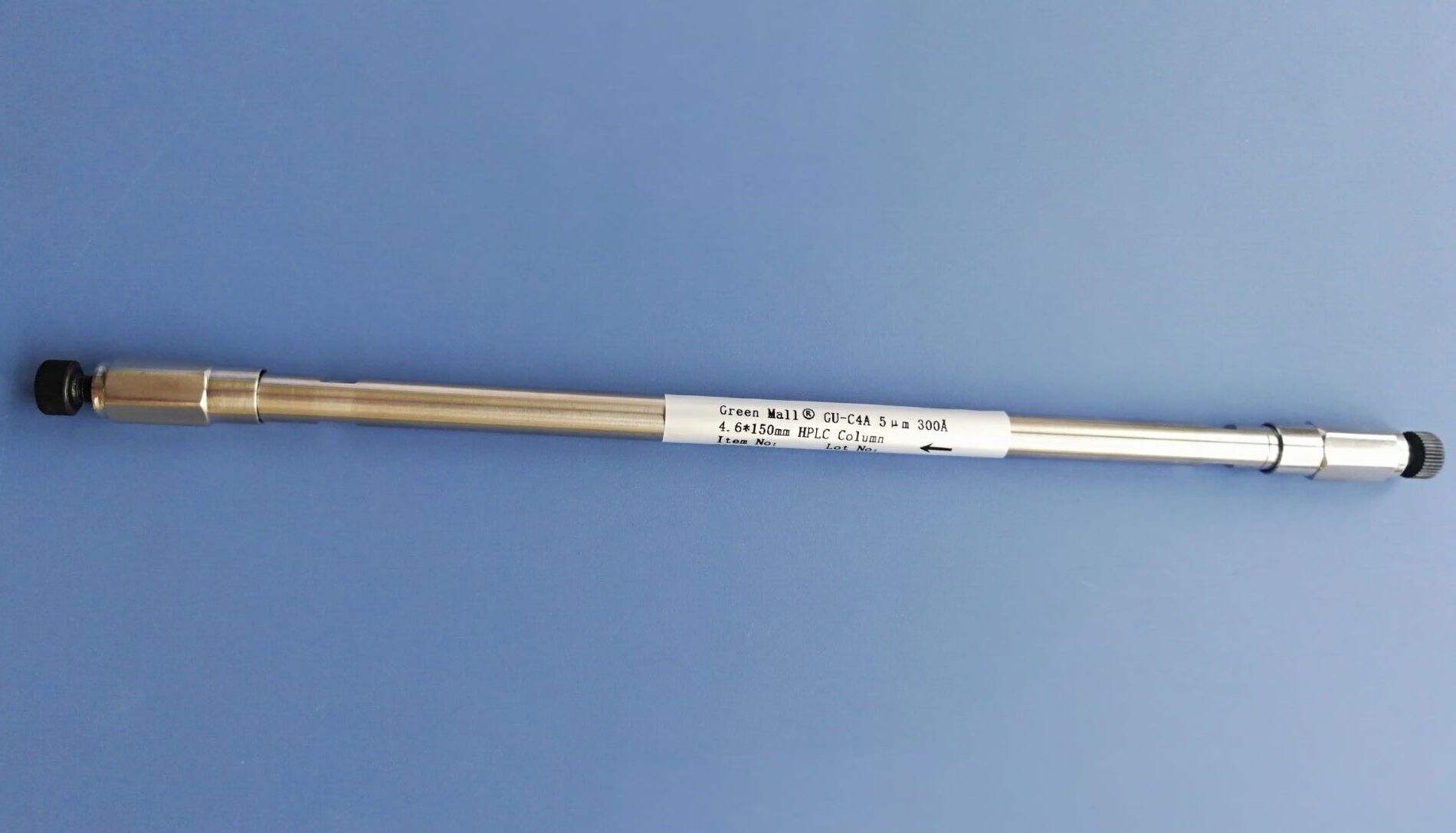

Column Dimensions and Configuration

The physical dimensions of the HPLC column, including length, internal diameter, and packed bed density, directly impact separation efficiency. Longer columns typically provide better resolution but at the cost of increased analysis time and backpressure. Column internal diameter affects sample loading capacity and sensitivity, with narrower columns generally offering better concentration sensitivity.

Column configuration must be matched to the analytical requirements, considering factors such as sample complexity, required resolution, and analysis time constraints. Modern column technology offers various options, from traditional formats to monolithic and micro-bore columns.

Temperature and Pressure Considerations

Temperature Control and Stability

Temperature plays a vital role in HPLC column efficiency by affecting mobile phase viscosity, diffusion rates, and analyte-stationary phase interactions. Precise temperature control ensures reproducible retention times and consistent peak shapes. Higher temperatures can improve efficiency by reducing mobile phase viscosity and enhancing mass transfer kinetics.

However, temperature must be carefully controlled to prevent thermal gradients within the column, which can lead to band broadening. Modern HPLC systems incorporate sophisticated temperature control mechanisms to maintain column stability throughout the analysis.

System Pressure Management

Operating pressure affects HPLC column efficiency through its influence on mobile phase compression and frictional heating. Excessive pressure can lead to column bed compression and reduced efficiency, while insufficient pressure may result in poor peak shapes and inadequate resolution. Understanding the pressure limitations of both the column and system is crucial for maintaining long-term performance.

Regular monitoring of system pressure helps identify potential issues such as column contamination or deterioration. Implementing appropriate preventive maintenance procedures ensures consistent HPLC column efficiency over time.

Sample-Related Factors

Injection Volume Optimization

The volume and concentration of injected samples significantly impact HPLC column efficiency. Overloading the column with excessive sample volumes or concentrations can lead to peak broadening and poor resolution. Optimal injection volumes typically represent a small fraction of the column void volume, usually less than 1%.

Sample solvent strength should match or be weaker than the mobile phase to prevent peak distortion. When working with complex matrices, sample preparation techniques such as dilution or cleanup may be necessary to maintain column efficiency.

Sample Matrix Effects

The composition of the sample matrix can significantly influence HPLC column efficiency through various mechanisms, including ion suppression, matrix-induced peak broadening, and column contamination. Proper sample preparation and matrix matching help minimize these effects and maintain consistent separation performance.

Implementation of appropriate sample cleanup procedures, such as filtration, extraction, or solid-phase extraction, helps protect column lifetime and maintain separation efficiency. Regular column cleaning and regeneration procedures may be necessary when working with complex sample matrices.

Frequently Asked Questions

How does pH affect HPLC column efficiency?

pH plays a crucial role in HPLC column efficiency by influencing analyte ionization state and interactions with the stationary phase. Proper pH control ensures consistent retention behavior and peak shapes. For optimal results, maintain pH within the column's specified operating range and use appropriate buffer systems to ensure pH stability throughout the analysis.

What are the signs of declining column efficiency?

Common indicators of declining HPLC column efficiency include increased peak tailing, decreased resolution between peaks, higher backpressure, and reduced plate numbers. Regular monitoring of these parameters through system suitability tests helps identify column performance issues early, allowing timely intervention and maintenance.

How can column lifetime be maximized while maintaining efficiency?

To maximize column lifetime while maintaining HPLC column efficiency, implement proper sample preparation procedures, use high-quality mobile phase solvents, maintain appropriate storage conditions, and follow manufacturer-recommended cleaning and regeneration protocols. Regular preventive maintenance and careful monitoring of operating conditions help ensure consistent performance over time.