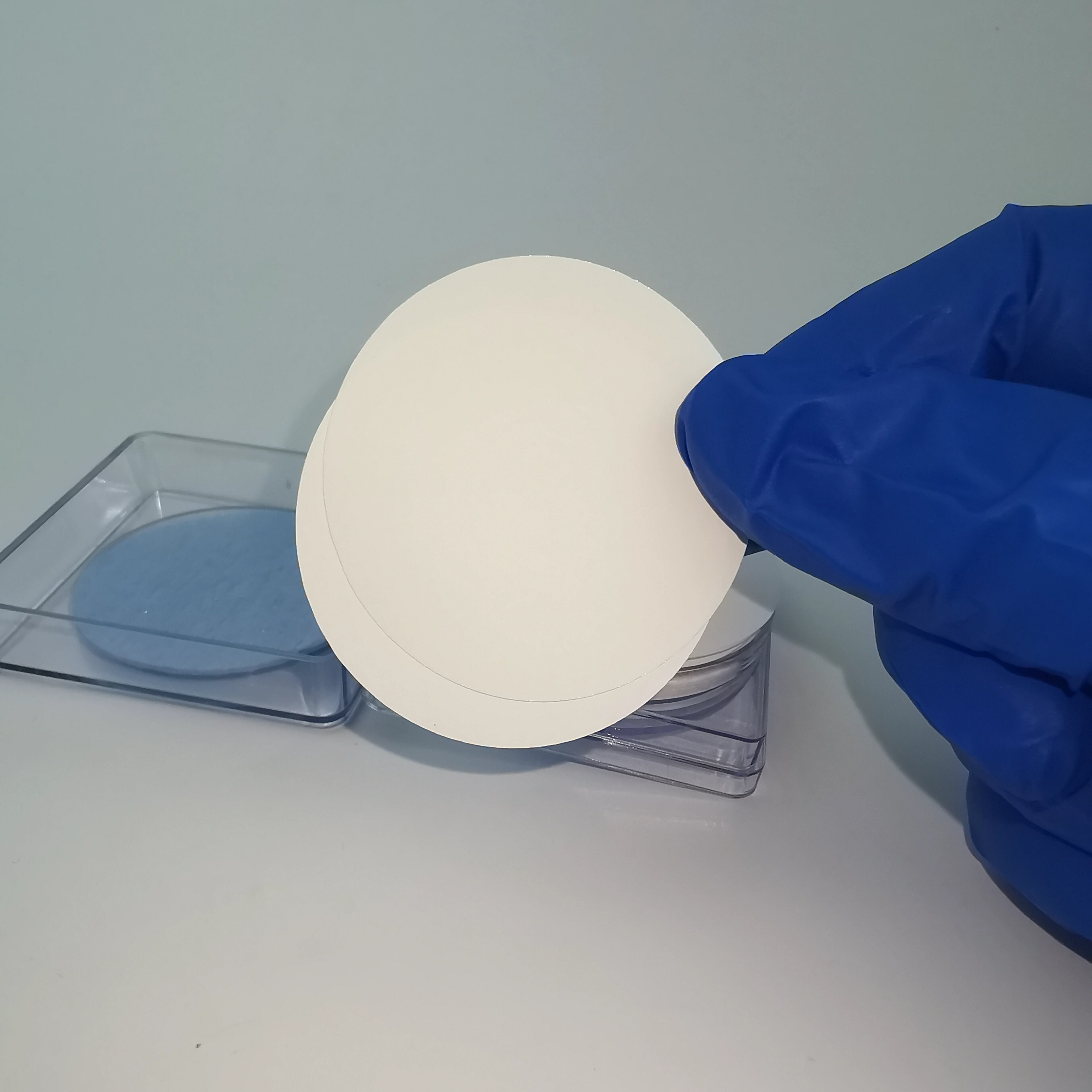

ช่วงการใช้งานที่หลากหลายและความสามารถในการปรับตัว

ໜຶ່ງແຫນວເປີເປັບສະດວກໃນການແຂວນຄົນໄປໃນອຸປະກອນທີ່ຕ່າງກັນຈາກການຄົ້ນຄວ້ນໃນລັບໂຮງເຖິງການປະຕິບັດໃນຊະນະອຸ່ນ. ການສະດວກຂອງມັນມາຈາກການປະສານກັນຂອງການຄື້ຍຂອງຂະແໜງ, ອົບເທກຳຂອງວັດຖຸ, ແລະ ການແປງປັບພິນ. ໃນການລົງທຶນແລະການແປງປັບຢາ, ເປີເປັບເຫ່ຍົ່ານີ້ແມ່ນການແກ້ວນິຕິການຂອງລູ້ນແລະການກັບຄື້ຍຂອງບາກເຕີເຣຍ. ໃນການລົງທຶນສິ່ງແວ່ນລົມ, ມັນຊ່ວຍໃຫ້ການວິເຄາະຄະນິກຂອງລູ້ນແລະການທົດສອບຄຳແນະນິຕິການນ້ຳ. ປະເທດອາຫານແລະເຄື່ອງດື່ມໄດ້ຮັບຜົນປະໂຫຍດຈາກການລົບລົງຄຳແນະນິຕິການຂອງລູ້ນເຖິງການປັບປຸງຄຳແນະນິຕິການຂອງສິນຄ້າ. ການປະຕິບັດຂອງມັນແຕ່ງໄປຫາການແກ້ວນິຕິການອາກາດ, ໂດຍທີ່ມັນສາມາດລົບລົງຄຳແນະນິຕິການຂອງລູ້ນແລະປັບປຸງການນຳເອົາອາກາດ. ເປີເປັບສາມາດຖືກປະສານເຂົ້າໃນລະບົບການແກ້ວນິຕິການທີ່ຕ່າງກັນ, ຈາກການຕັ້ງຄ່າລັບໂຮງທີ່ແຂວນໄປຫາການປະຕິບັດອຸ່ນອັດຕະໂມ. ການແຂວນຄົນນີ້, ໂດຍທີ່ມັນປະສານກັບການປະຕິບັດທີ່ສະເໝັກ, ເຮັດໃຫ້ເປີເປັບເປັນອຸປະກອນທີ່ມີຄ່າສູງໃນອຸ່ນທີ່ຕ່າງກັນແລະການປະຕິບັດ.