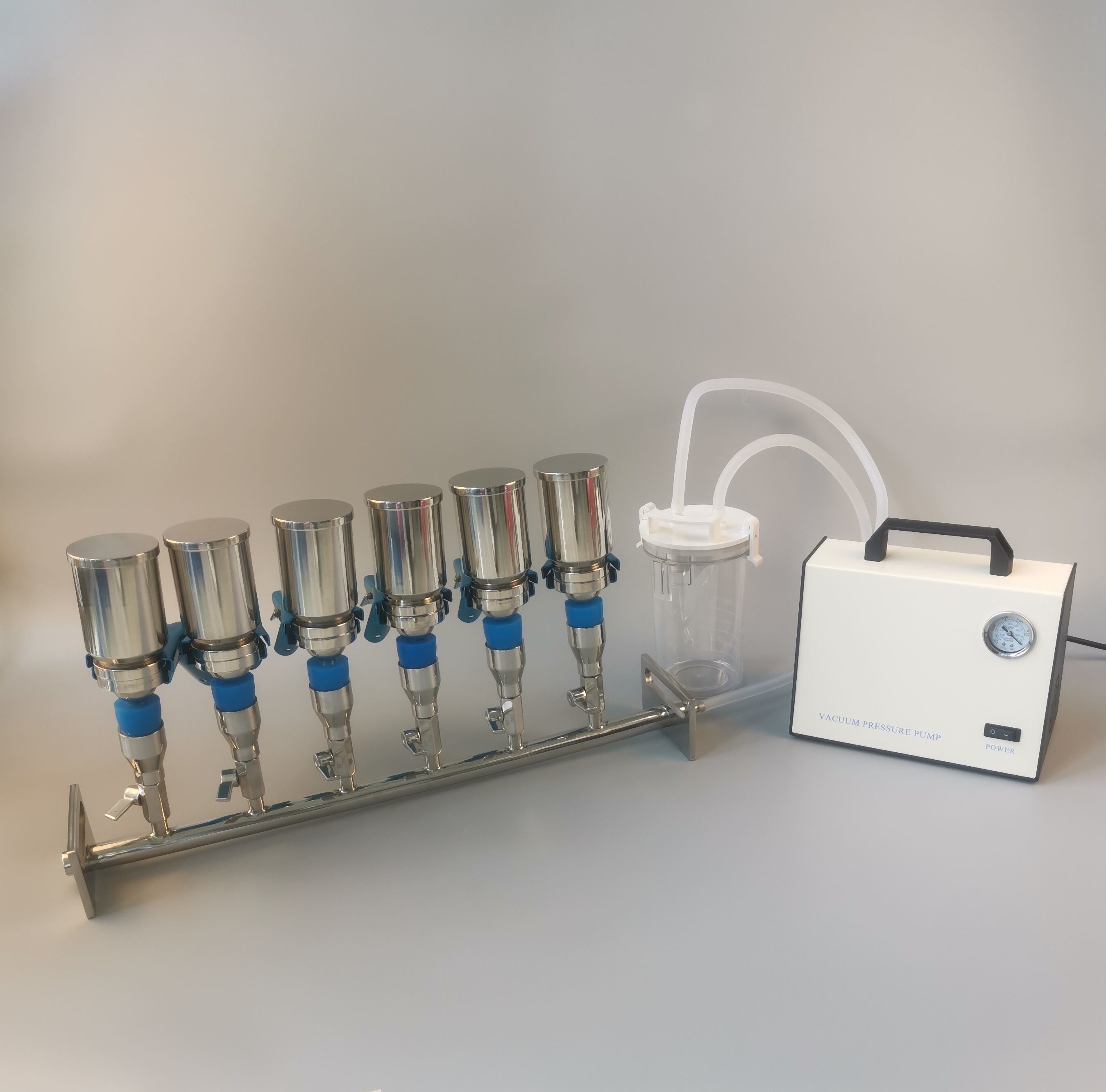

მრავალ გაłęებიანი ვაკუუმის ფილტრაციის სისტემა

Რამოდენიმე გაłęწიველის ფილტრაციის სისტემა წარმოადგენს საკმარის ამოხსნას ეფექტური ნაწილაკების განშარებისა და ღირძელის გამაგრებისთვის რამოდენიმე მარშრუტზე ერთდროულად. ეს მოდერნული სისტემა იнтეგრირებს რამოდენიმე ფილტრაციის გაłęწიველს, რომლებიც მიერთებულია ცენტრალურ ვაკუუმურ წყაროსთან, რათომ შესაძლებელია განსხვავებული ნიმუშების ან მასალების პარალელური გამოსაобработვა. თითოეული გაleysი მუშაობს მომდევნოდ, მოიცავს განსაკუთრებულ ფილტრის მაჩვენებლებს, კრებადი ვაზებს და ზუსტ ვაკუუმურ კონტროლის მექანიზმებს. სისტემის დიზაინი შეიცავს მაღალ ხარისხის მასალებს, როგორიცაა ბოროსილიკატური სურსი, რეზისტენტული ნიკელი და ქიმიურად მაღალი რეზისტენტული პოლიმერები, რაც უზრუნველყოფს დამაგრებას და საშუალებას გათვალისწინებული ქიმიური გარემოებით. ტექნოლოგია იყენებს დიფერენციალურ წნევის პრინციპებს, შექმნის კონტროლირებულ ვაკუუმურ პირობებს, რაც აჩქარებს ფილტრაციას და მაინტეგრირებს ნიმუშის მთავრობას. მთავარი კომპონენტები მოიცავს ვაკუუმურ მანიფოლდებს, ინდივიდუალურ მოსულის კონტროლის ბალანსებს, წნევის მეტრებს და სპეციალურ ფილტრაციის მაჩვენებლებს. სისტემა მხარდაჭერს განსხვავებულ ტიპების ფილტრებს, იდეალურად მემბრანული ფილტრებიდან მისაღები ფილტრებისამდე, რომლებიც შეიცავს ნაწილაკებს ქვე-მიკრონიდან რამდენიმე მიკრონამდე. გამოყენება შეიცავს ფარმაცევტულ წარმოებას, ქიმიურ გამოსაобработვას, გარემოების ტესტებს და ექსპერიმენტულ ლაბორატორიებს, სადაც რამოდენიმე ნიმუშის ფილტრაცია საჭიროა კონტროლირებულ პირობებში. სისტემის მოდულარული დიზაინი უზრუნველყოფს მარტივ გაფართოებას ან რეკონფიგურაციას, ხოლო შენახური საუსამართლო მახასიათებები აკრძალებს კროს-დაბრუნებას და უზრუნველყოფს მართვის მარტივ მუშაობას.