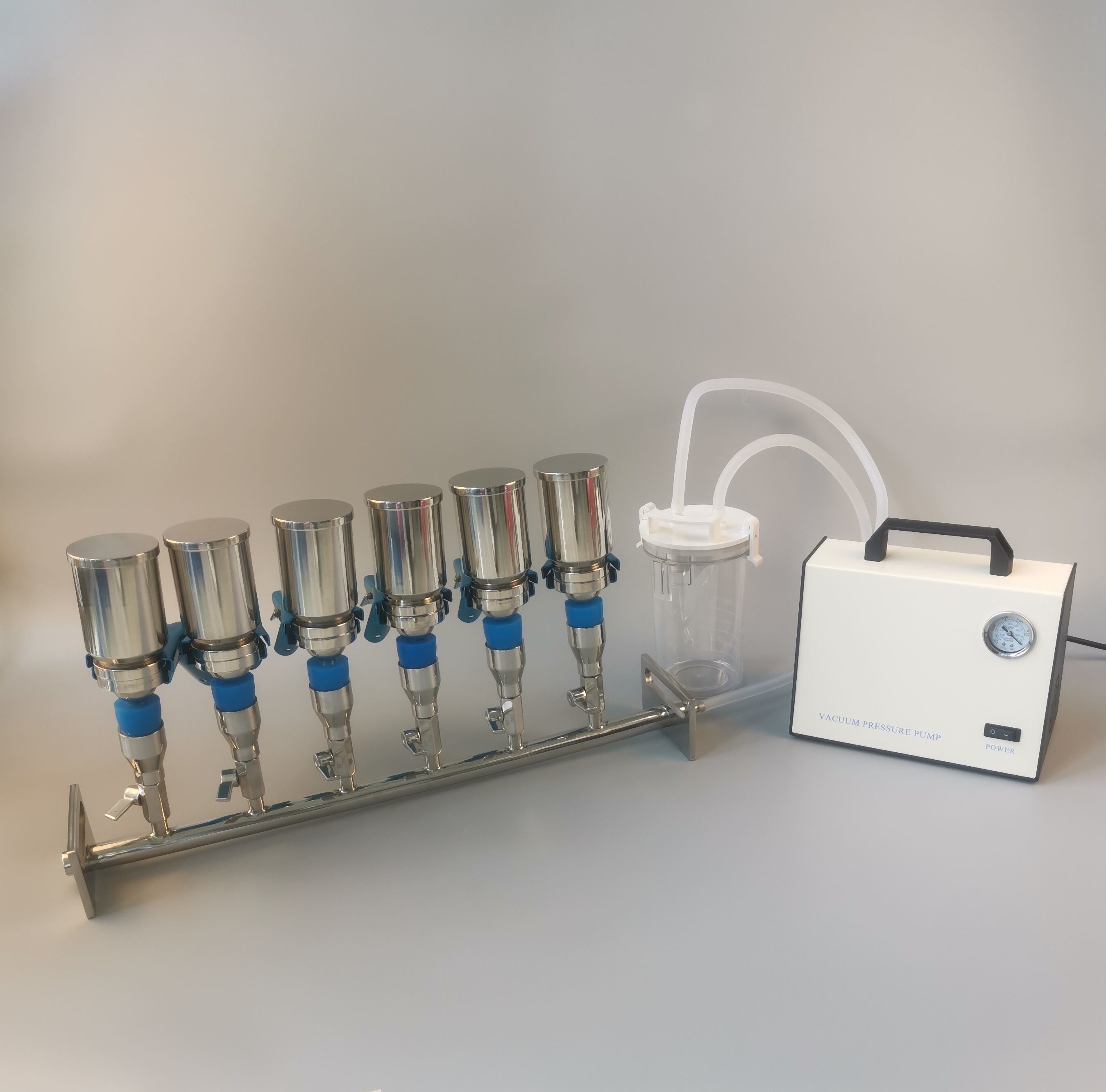

سیستم فیلتراسیون شوایع چند شاخه ای

یک سیستم فیلتراسیون شوایع چند شاخهای نمایانگر یک راهحل پیشرفته برای جداسازی ذرات کارآمد و تصفیه مایعات در بین جریانهای متعدد به صورت همزمان است. این سیستم پیشرفته چندین شاخه فیلتراسیون را که به منبع خلاء مرکزی متصل هستند، ادغام میکند و پردازش موازی نمونهها یا مواد مختلف را امکانپذیر میسازد. هر شاخه به طور مستقل عمل میکند و شامل حاملهای فیلتر اختصاصی، ظروف جمعآوری و مکانیسمهای کنترل دقیق خلاء است. طراحی این سیستم از مواد با کیفیت بالا مانند شیشه بوروسیلیکات، فولاد راستالحکم و پلیمرهای مقاوم به مواد شیمیایی استفاده میکند که محکبودن و سازگاری با محیطهای شیمیایی مختلف را تضمین میکند. فناوری این سیستم از اصول فشار دیفرانسیل استفاده میکند و شرایط خلاء کنترلشدهایجاد میکند که فیلتراسیون را تسریع میکند بدون آنکه از بینقص بودن نمونهها کاسته شود. مؤلفههای اصلی شامل منیفولد خلاء، مقداردهیهای کنترل جریان انفرادی، سنجندههای فشار و حاملهای اختصاصی فیلتراسیون هستند. این سیستم از انواع مختلف فیلتر پشتیبانی میکند، از فیلترهای ممبرانی تا فیلترهای عمقی، و اندازه ذرات را از زیر میکرون تا چندین میکرون پوشش میدهد. کاربردها از تولید دارویی، پردازش شیمیایی، آزمایش محیط زیست تا آزمایشگاههای تحقیقاتی گسترش مییابد، جایی که نیاز به فیلتراسیون همزمان نمونههای متعدد تحت شرایط کنترلشده وجود دارد. طراحی ماژولار این سیستم امکان گسترش آسان یا بازپیکربندی را فراهم میکند، در حالی که ویژگیهای ایمنی داخلی جلوگیری از آلودگی متقابل و اطمینان از عملکرد قابل اعتماد را تضمین میکند.