Ֆիլտրացման տեխնոլոգիայի էվոլյուցիան ժամանակակից արդյունաբերության մեջ

Արդյունաբերական և լաբորատոր ֆիլտրացման անընդհատ զարգացող ոլորտում թաղանթային ֆիլտրները առանձնացման և մաքրման գործընթացների համար դարձել են ոսկե ստանդարտ: Այս բարդ ֆիլտրացման լուծումները փոխակերպել են այն կերպ, որ արդյունաբերությունները պահպանում են արտադրանքի որակը, ապահովում են հետազոտությունների ճշգրտությունը և համապատասխանում են կանոնակարգային պահանջներին: Թաղանթային ֆիլտրների հիանալի բազմակողմանիությունն ու արդյունավետությունը դրանք անփոխարինելի են դարձրել դեղագործական արտադրության, ջրի մաքրման, սննդի և ըմպելիքների արտադրության, ինչպես նաև առաջատար գիտական հետազոտությունների ոլորտներում:

Թաղանթային ֆիլտրների ճանապարհը՝ սկսած հատուկ լաբորատոր սարքավորումներից մինչև լայն արդյունաբերական կիրառությունները, ցույց է տալիս դրանց փոխակերպողական ազդեցությունը որակի վերահսկման և գործընթացների օպտիմալացման վրա: Քանի որ արդյունաբերությունները կենտրոնանում են ավելի բարձր մաքրության ստանդարտների և ավելի արդյունավետ առանձնացման գործընթացների վրա, թաղանթային ֆիլտրները շարունակում են ապացուցել իրենց արժեքը՝ առաջարկելով գերազանց կատարում և հուսալիություն:

Թաղանթային ֆիլտրի տեխնոլոգիայի հասկացությունը

Հիմնական բաղադրիչներ և կառուցվածք

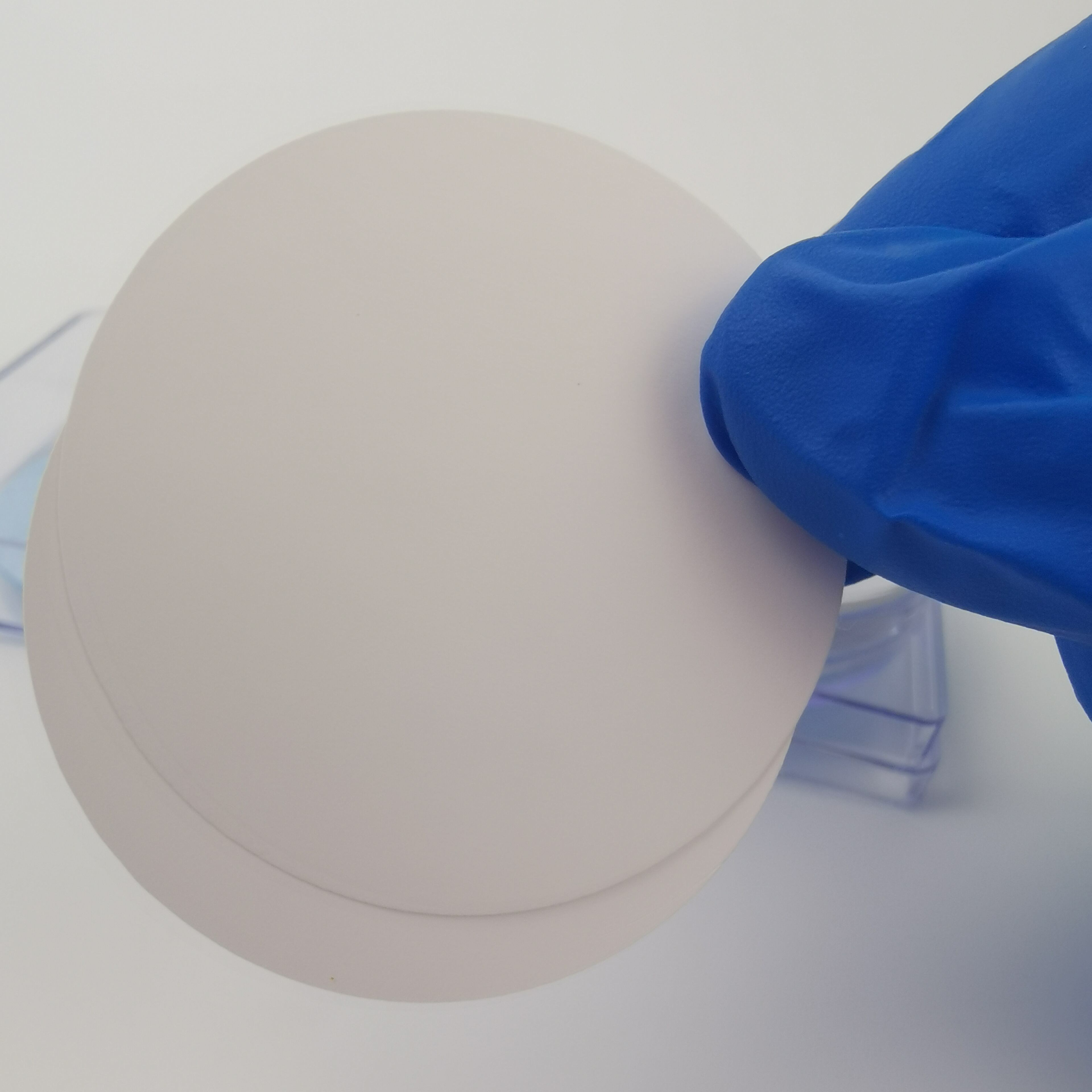

Հիմնական մակարդակում թաղանթային ֆիլտրները կազմված են ճշգրիտ ինժեներական միկրոանցքերով նյութերից, որոնք նախագծված են մասնիկները ըստ չափի, լիցքի կամ մոլեկուլային հատկանիշների բաժանելու համար: Թաղանթի կառուցվածքը սովորաբար ներառում է փոխկապված անցքերի ցանց, որոնք կարող են տատանվել մի քանի միկրոմետրից մինչև նանոմետրային սանդղակ: Այս բարդ կառուցվածքը հնարավորություն է տալիս բարձրասելեկտիվ ֆիլտրման, միևնույն ժամանակ պահպանելով հաստատուն հոսքի արագությունը և նվազագույն ճնշման անկում:

Գերազանց արտադրական տեխնիկաները թույլ են տալիս թաղանթային ֆիլտրների արտադրություն տարբեր նյութերից, ներառյալ պոլիէթերսուլֆոն (PES), պոլիվինիլիդեն ֆտորիդ (PVDF) և նայլոն: Յուրաքանչյուր նյութ ունի հատուկ առավելություններ տարբեր կիրառությունների համար՝ սկսած գերազանց քիմիական դիմադրությունից մինչև սպիտակուցների կապման հատկությունների բարելավում:

Ֆիլտրման մեխանիզմներ և սկզբունքներ

Մեմբրանային ֆիլտրերը գործում են մի քանի մեխանիզմներով, ներառյալ չափի բացառում, խորության ֆիլտրացում և մակերեսային ունկնդրում: Հիմնական ֆիլտրացման մեխանիզմը կախված է մեմբրանի կառուցվածքից և կիրառման հատուկ պահանջներից: Չափի բացառումը, ամենապարզ մեխանիզմը, աշխատում է՝ ֆիզիկապես արգելակելով այն մասնիկները, որոնք մեծ են մեմբրանի անցքերի չափից, մինչդեռ թույլ է տալիս ավելի փոքր մոլեկուլներին անցնել:

Ավելի բարդ մեմբրանային ֆիլտրերը ներառում են լրացուցիչ բաժանման մեխանիզմներ, ինչպիսիք են լիցքի հիման վրա բաժանումը կամ աֆին կապումը, ինչը հնարավորություն է տալիս հեռացնել այն աղտոտիչները, որոնք հակառակ դեպքում կանցնեին միայն չափի հիման վրա: Ֆիլտրացման այս բազմառումբ մոտեցումը ապահովում է գերազանց արդյունավետություն լայն շրջանակի կիրառություններում:

Գերազանց առավելություններ լաբորատոր կիրառություններում

Ճշգրտություն և վերարտադրելիություն

Լաբորատորիաներում թաղանթային ֆիլտրները գերազանցում են՝ ապահովելով աննախադեպ ֆիլտրման ճշգրտություն և հաստատունություն: Դրանց համաչափ անցքերի կառուցվածքը ապահովում է մասնիկների վստահելի առանձնացում, ինչը դարձնում է այն իդեալական անալիտիկ գործընթացների և նմուշների պատրաստման համար: Գիտնականները կարող են վստահորեն հիմնվել թաղանթային ֆիլտրների վրա՝ ստանալով վերարտադրվող արդյունքներ, որոնք կարևոր են փորձարարական վավերականության և հետազոտության ամբողջականության պահպանման համար:

Թույլատրելով ճշգրիտ կեղծափողների պարամետրերի վերահսկում թաղանթային ֆիլտրերի միջոցով՝ հնարավոր է լաբորատորիաների համար ստանդարտացնել իրենց պրոցեդուրաները և ստանալ համապատասխան արդյունքներ բազմաթիվ փորձերի կամ փորձարկման ընթացակարգերի ընթացքում: Այս ստանդարտացումը հատկապես կարևոր է որակի վերահսկողության լաբորատորիաներում և հետազոտական հաստատություններում, որտեղ վերարտադրությունը առաջնային նշանակություն ունի:

Տարբեր անալիզի մեթոդների հետ համատեղելիություն

Ժամանակակից թաղանթային ֆիլտրերը նախագծված են անալիզի տարբեր մեթոդների և լաբորատոր ընթացակարգերի հետ համատեղելի լինելու համար: Դրանց քիմիական իներտությունը կանխում է նմուշի անալիզի մեջ միջամտությունը, իսկ ցածր էքստրակտային ցուցանիշը ապահովում է նվազագույն ազդեցություն զգայուն անալիտիկ մեթոդների վրա: Այս բազմակողմանիությունը դարձնում է դրանք հարմար հետևյալ կիրառությունների համար՝ HPLC նմուշի պատրաստումից մինչև միկրոկենսաբանական անալիզ:

Թաղանթային ֆիլտրերի տարբեր անալիզի մեթոդներին հարմարվելու հնարավորությունը տարածվում է նաև ավտոմատացված լաբորատոր համակարգերի ինտեգրման վրա, որը բարելավում է աշխատանքային գործընթացի արդյունավետությունը և նվազեցնում է ձեռքով մշակման անհրաժեշտությունը: Այս անընդհատ համատեղելիությունը նպաստում է ավելի արագ մշակման ժամանակահատվածներին և լաբորատորիայի արտադրողականության բարելավմանը:

Արդյունաբերական կիրառումներ և առավելություններ

Գործընթացի օպտիմալացում և արդյունավետություն

Արդյունաբերական պայմաններում թաղանթային ֆիլտրները դարձել են արտադրության գործընթացների օպտիմալացման և արտադրանքի որակի ապահովման համար կարևոր միջոց: Դրանց բարձր թափանցելիությունը և կայուն շահագործման հատկանիշները թույլ են տալիս անընդհատ աշխատանք՝ նվազագույն կանգնելով սպասարկման կամ փոխարինման համար: Արդյունաբերությունները շահում են նվազացված մշակման ժամանակից և բարելավված շահագործման արդյունավետությունից, ինչը թարգմանվում է նշանակալի կորուստների կրճատման:

Թաղանթային ֆիլտրների կիրառումը արդյունաբերական գործընթացներում հաճախ էներգախնայողության է հանգեցնում համեմատած ավանդական ֆիլտրացման մեթոդների հետ: Դրանց արդյունավետ կառուցվածքը նվազագույնի է հասցնում ճնշման կորուստները և օպտիմալացնում է հոսքի արագությունը, ինչը նվազեցնում է շահագործման ծախսերը՝ պահպանելով գերազանց ֆիլտրացման կարողություն:

Պահով ու կարգավորման բաժանում և կանոնական համաձայնություն

Սահմանափակ կարգավորող պահանջներին ենթարկվող արդյունաբերությունների համար թաղանթային ֆիլտրերը հուսալի միջոց են ապահովում համապատասխանության ստանդարտների հասնելու և պահպանելու համար: Նրանց վավերացված աշխատանքը և հետևելիության հատկությունները աջակցում են որակի կառավարման համակարգերի համար անհրաժեշտ փաստաթղթերի պահանջներին: Աղտոտիչների և մասնիկների համապատասխան հեռացումը օգնում է արդյունաբերություններին համապատասխանել արտադրանքի սպեցիֆիկացիաներին և կարգավորող հղումներին:

Մեմբրանային ֆիլտրերին կցված փաստաթղթավորման և վավերացման հնարավորությունները հեշտացնում են աուդիտի գործընթացներն ու կանոնակարգման ստուգումները: Արտադրական սարքերը կարող են անմիջապես ցուցադրել իրենց նվիրվածությունը որակի վերահսկմանը և համապատասխանմանը՝ մատչելի դարձնելով հիմնավորված ֆիլտրման վավերացման տվյալներ և աշխատանքի գրառումներ:

Շրջակա միջավայրի և կայունության հարցեր

Ռեսուրսների պահպանություն

Թաղանթային ֆիլտրերի կիրառումը զգալիորեն նպաստում է շրջակա միջավայրի կայունությանը տարբեր արդյունաբերություններում: Դրանց արդյունավետ ֆիլտրացման հնարավորությունները նվազեցնում են ջրի օգտագործումը մշակման գործընթացներում, իսկ դիմացկունությունը երկարաձգում է շահագործման ժամկետը համեմատած ավանդական ֆիլտրացիոն միջավայրերի հետ: Այս երկարակեցությունը հանգեցնում է ավելի հազվադեպ փոխարինման և թափոնների առաջացման նվազման:

Թաղանթային ֆիլտրերի առաջադեմ կոնստրուկցիաները ներառում են այնպիսի հատկանիշներ, որոնք նվազեցնում են ֆիլտրացման գործընթացների շրջակա միջավայրի վրա ունեցած ազդեցությունը, ինչպիսիք են մաքրման ընթացքում քիմիական նյութերի նվազագույն օգտագործումը և շահագործման ընթացքում էներգաօգտագործման արդյունավետության բարելավումը: Այս հատկանիշները համընկնում են արդյունաբերության մեջ կայուն արտադրության գործընթացների համար ձեռնարկվող աճող նախաձեռնությունների հետ:

Թափոնների նվազեցում և վերականգնում

Մեմբրանային ֆիլտրները թույլ են տալիս վերականգնել և վերամշակել այն գործընթացային նյութերը, որոնք այլապես կկորցվեին ավելի քիչ արդյունավետ ֆիլտրման մեթոդների դեպքում: Այս հնարավորությունը ոչ միայն նվազեցնում է թափոնները, այլ նաև բարելավում է ռեսուրսների օգտագործումը և շահագործման տնտեսական ցուցանիշները: Արդյունաբերությունները կարող են իրականացնել փակ օղակաձև համակարգեր, որոնք առավելագույնի հասցնում են նյութերի վերականգնումը՝ նվազագույնի հասցնելով շրջակա միջավայրի վրա ունեցած ազդեցությունը:

Մեմբրանային ֆիլտրացման ճշգրտությունը հնարավորություն է տալիս գործընթացային հոսքերից ընտրողաբար վերականգնել բարձր արժեք ունեցող բաղադրիչներ, ինչը նպաստում է ինչպես շրջակա միջավայրի կայունությանը, այնպես էլ տնտեսական արդյունավետությանը: Կրկնակի առավելությունը մեմբրանային ֆիլտրներին դարձնում է հատկապես գրավիչ այն արդյունաբերությունների համար, որոնք կենտրոնացած են իրենց շրջակա միջավայրի վրա ունեցած ազդեցությունը նվազեցնելու վրա:

Հաճախ տրվող հարցեր

Ինչո՞ւ են մեմբրանային ֆիլտրները ավելի արդյունավետ, քան ավանդական ֆիլտրման մեթոդները:

Մեմբրանային ֆիլտրները ապահովում են գերազանց ֆիլտրացման արդյունավետություն՝ ճշգրիտ վերահսկվող անցքերի չափերի, համասեռ մասնիկների պահման և կայուն աշխատանքային բնութագրերի շնորհիվ: Դրանց առաջադեմ նյութերն ու արտադրության գործընթացները ապահովում են բարձր հուսալիություն և վերարտադրելիություն համեմատած սովորական ֆիլտրացման մեթոդների հետ, իսկ դրանց բազմակի կիրառելիությունը թույլ է տալիս օգտագործել այն տարբեր արդյունաբերական և լաբորատոր պայմաններում:

Որքա՞ն է մեմբրանային ֆիլտրների սովորական կյանքի տևողությունը արդյունաբերական կիրառություններում:

Մեմբրանային ֆիլտրների շահագործման կյանքի տևողությունը տարբերվում է՝ կախված կիրառությունից, գործընթացի պայմաններից և սպասարկման միջոցառումներից: Ճիշտ խնամքի և կանոնավոր մաքրման գործընթացների դեպքում արդյունաբերական մեմբրանային ֆիլտրները կարող են պահպանել իրենց օպտիմալ աշխատանքային հատկանիշները մի քանի ամիսից մինչև մի քանի տարի: Կանոնավոր հսկողությունը և կանխարգելիչ սպասարկումը կարող է զգալիորեն երկարաձգել դրանց ծառայողական կյանքը:

Արդյո՞ք մեմբրանային ֆիլտրները տնտեսապես արդյունավետ են փոքր մասշտաբի գործողությունների համար:

Չնայած թաղանթային ֆիլտրման համակարգերի սկզբնական ներդրումը կարող է ավելի բարձր լինել, քան ավանդական տարբերակներինը, երկարաժամկետ առավելությունները հաճախ արդարացնում են ծախսերը՝ նույնիսկ փոքր մասշտաբներով գործողությունների դեպքում: Բարելավված արտադրանքի որակը, նվազած շահագործման ծախսերը, նվազած սպասարկման պահանջները և երկարացված ֆիլտրի կյանքը նպաստում են գործողությունների տարբեր մասշտաբներում ներդրման ներդրման դրական վերադարձին: