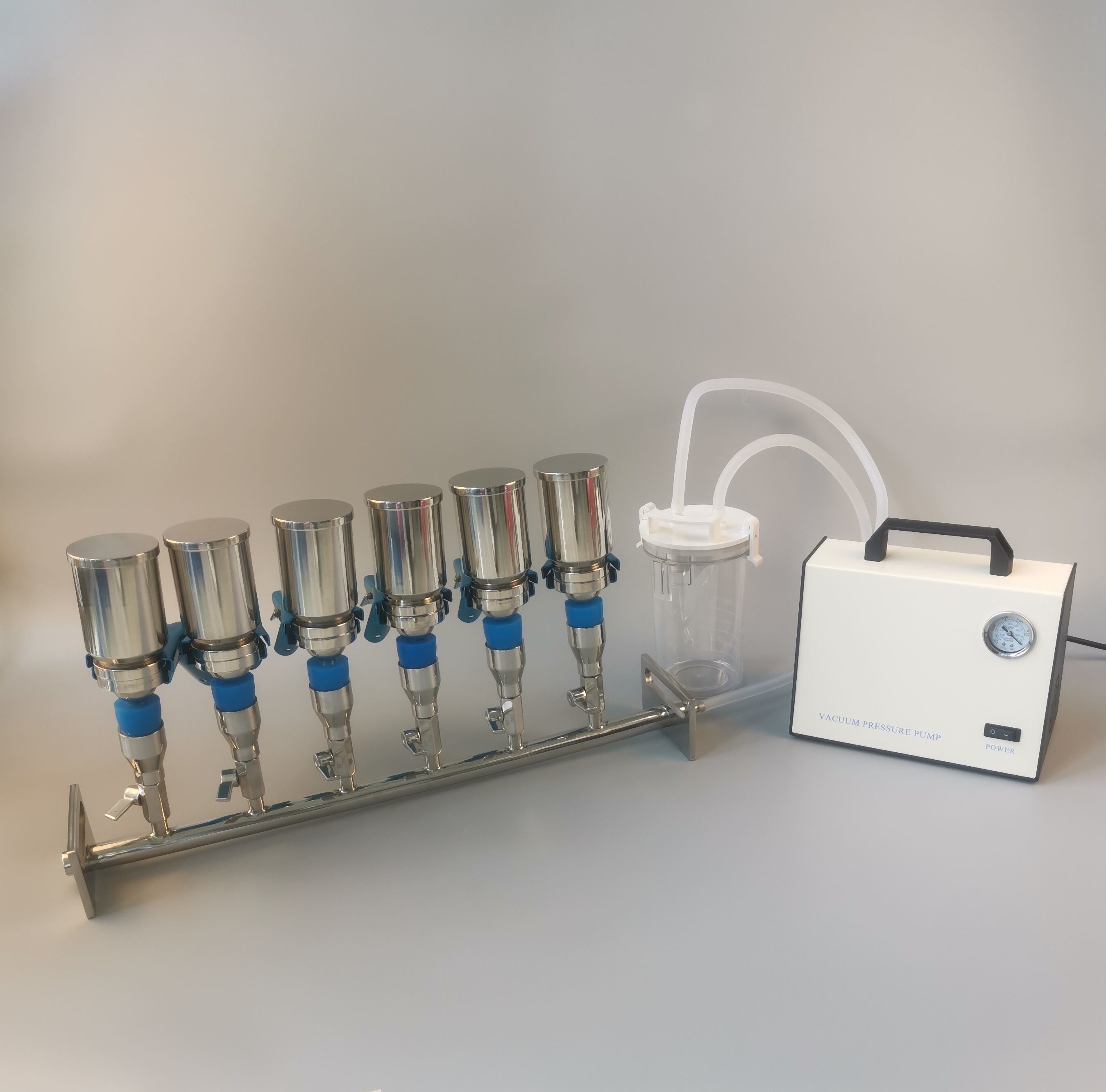

vacuum filtration for chemical analysis

Vacuum filtration for chemical analysis is a fundamental laboratory technique that efficiently separates solids from liquids by creating a pressure differential. This method employs a vacuum pump connected to a filtering flask, which generates suction to draw the liquid through a filter paper while retaining solid particles. The setup typically consists of a Buchner funnel, filter paper, filtering flask, and vacuum source. The process accelerates filtration significantly compared to gravity filtration, making it invaluable for time-sensitive analyses. The technique is particularly effective for collecting fine precipitates and handling large volumes of solutions. Modern vacuum filtration systems incorporate advanced features such as precise pressure control, chemical-resistant materials, and various filter media options to accommodate different particle sizes and chemical compositions. The method finds extensive applications in quality control laboratories, environmental testing, pharmaceutical research, and academic institutions. It enables researchers to perform accurate quantitative analyses, isolate compounds for further study, and prepare samples for instrumental analysis. The technology has evolved to include automated systems with digital pressure monitoring and programmable operation sequences, enhancing reproducibility and efficiency in analytical procedures.