hydrofob filtermembran

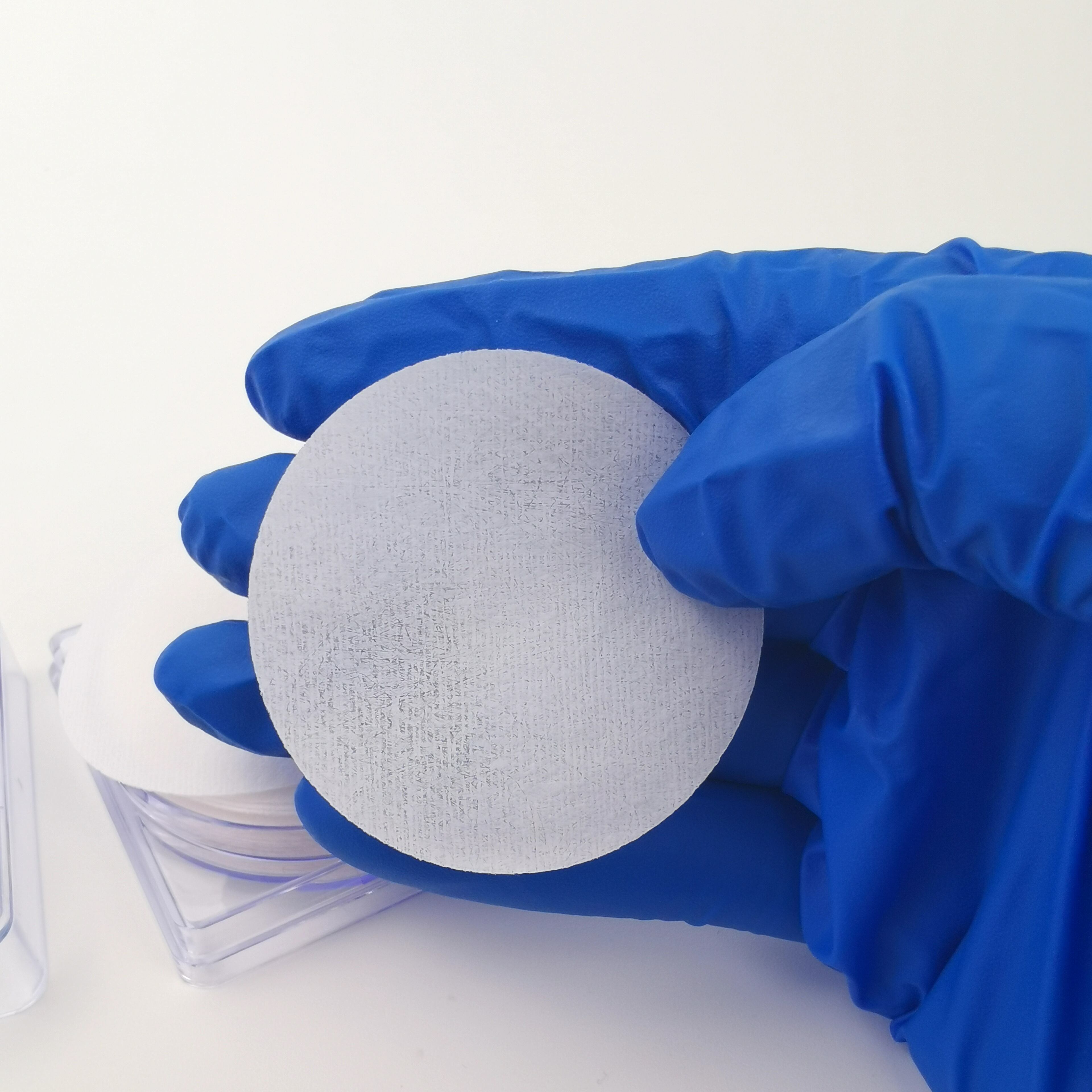

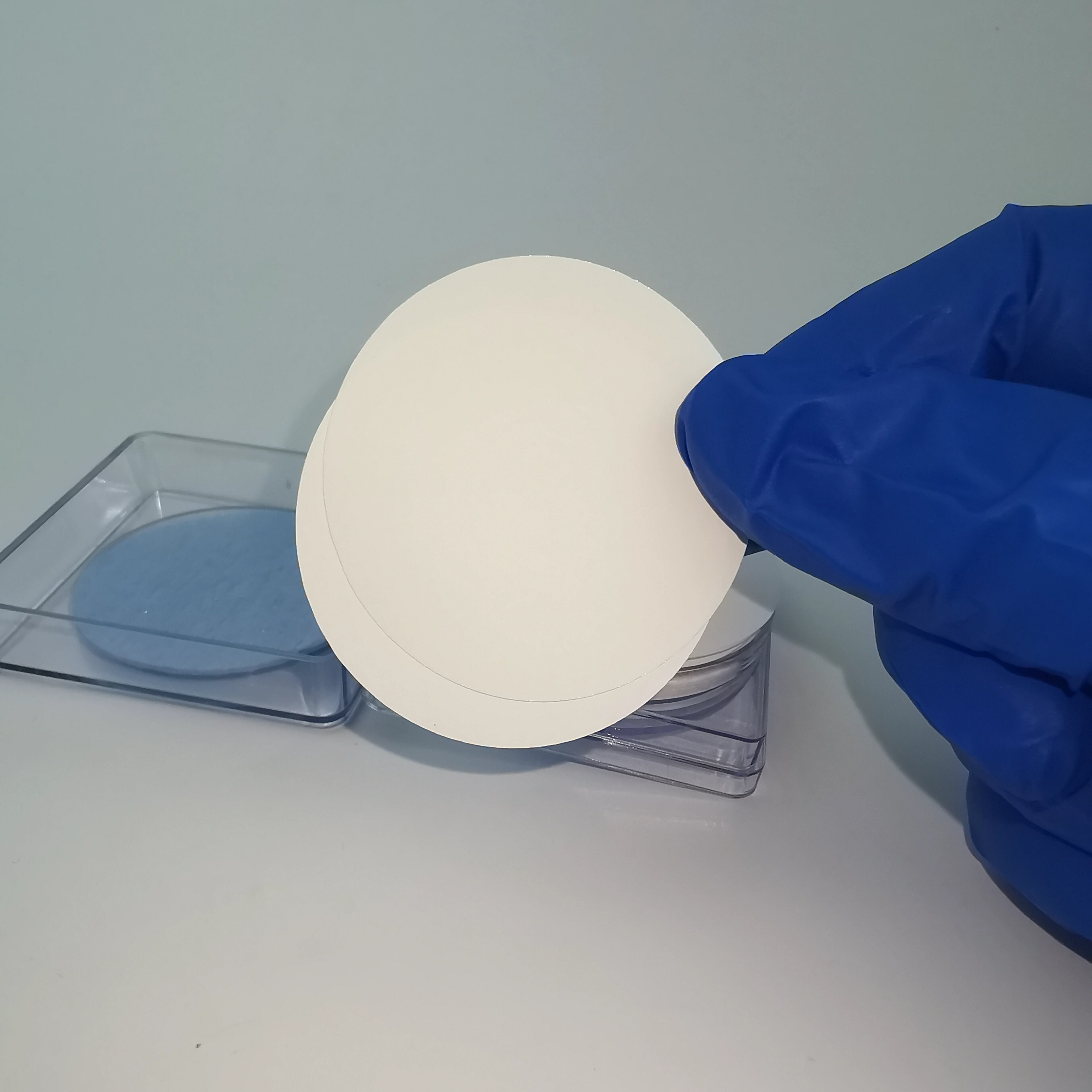

En hydrofob filtermembran representerar en avgörande framsteg inom filtreringstekniken, utformad specifikt för att avvisa vatten samtidigt som luft och andra gaser kan passera genom effektivt. Denna specialiserade membran konstrueras av olika polymerica material, såsom PTFE, PVDF eller polypropylen, vilka är inhämtat vattenavvisande. Membranets yta är utformat med mikroskopiska porer som skapar en barriär mot vätskeintrång samtidigt som den bibehåller utmärkt gaspermeabilitet. Grundläggande arbetsprincipen bygger på membranets låga ytförädling, vilket förhindrar att vattnets molekyler tränger in i porerna medan gaser kan flöda fritt. Dessa membran har vanligtvis porstorlekar som varierar mellan 0,1 till 1,0 mikroner, vilket erbjuder precist kontroll över filtreringskraven. I praktiska tillämpningar är hydrofoba filtermembran nödvändiga komponenter i medicinska enheter, laboratorieutrustning och industriella processer där det är avgörande att bibehålla en barriär mellan vätskor och gaser. Tekniken har visat sig särskilt värdefull i tillämpningar som blodoxigenatorer, luftventil för vätskehanteringssystem och skydd av känslig elektronisk utrustning från fuktskada. Membranets förmåga att bibehålla sina vattenavvisande egenskaper samtidigt som det förblir permeabelt för gas gör det till en oumbärlig lösning för många kritiska tillämpningar på flera områden.