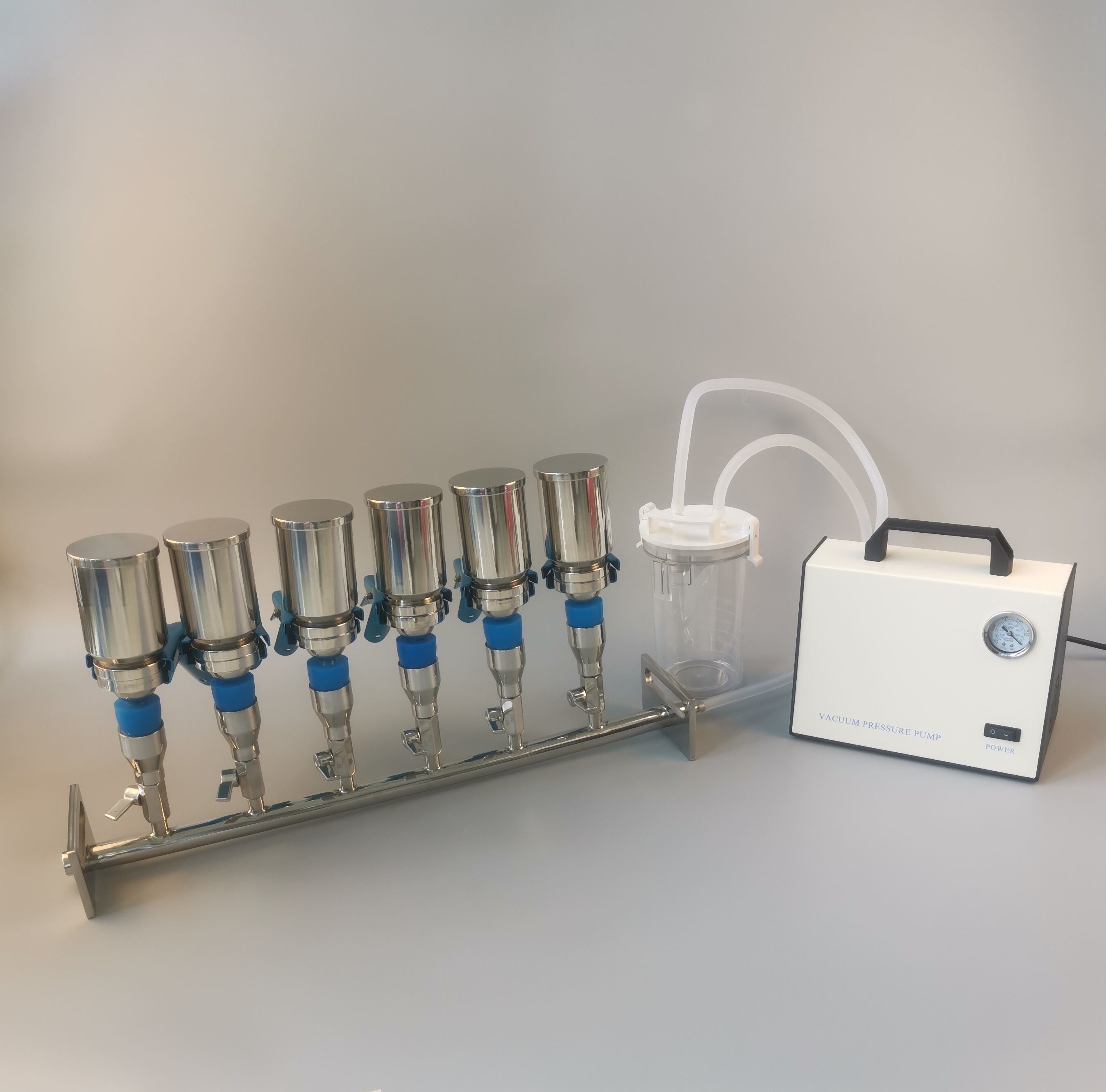

φίλτρο κενού για χρήση στο εργαστήριο

Το φίλτρο κενού για εργαστηριακή χρήση είναι ένα απαραίτητο εξαρτήμα εξοπλισμού που έχει σχεδιαστεί για τον διαχωρισμό στερεών από υγρών μέσω φιλτραρίσματος με υποβοήθηση κενού. Αυτή η εξελιγμένη συσκευή συνδυάζει ακριβή μηχανική με ευέλικτη λειτουργικότητα, καθιστώντας την απαραίτητη σε σύγχρονα εργαστηριακά περιβάλλοντα. Το σύστημα συνήθως αποτελείται από πηγή κενού, φιάλη διήθησης, στήριξη φίλτρου και εξειδικευμένα μέσα φίλτρου. Λειτουργώντας με την αρχή της διαφορικής πίεσης, δημιουργεί ένα κενό περιβάλλον που επιταχύνει σημαντικά τη διαδικασία φιλτραρίσματος σε σύγκριση με τις μέθοδοι διήθησης με βαρύτητα. Η συσκευή διαθέτει ρυθμιζόμενα συστήματα ελέγχου πίεσης κενού, που επιτρέπουν στους ερευνητές να ρυθμίζουν τη ταχύτητα διήθησης σύμφωνα με τις ειδικές απαιτήσεις των δειγμάτων. Τα προηγμένα μοντέλα περιλαμβάνουν ψηφιακές οθόνες για ακριβή παρακολούθηση της πίεσης και αυτοματοποιημένα συστήματα ρύθμισης της πίεσης. Η κατασκευή του εξοπλισμού χρησιμοποιεί συνήθως χημικά ανθεκτικά υλικά όπως γυαλί βοροσιλικικού και υψηλής ποιότητας ανοξείδωτο χάλυβα, εξασφαλίζοντας αντοχή και συμβατότητα με διάφορες χημικές ενώσεις. Οι εφαρμογές εκτείνονται σε πολλαπλές επιστημονικές επιστήμες, συμπεριλαμβανομένης της χημικής ανάλυσης, της φαρμακευτικής έρευνας, των περιβαλλοντικών δοκιμών και των μικροβιολογικών μελετών. Το σύστημα υπερέχει σε εργασίες όπως η προετοιμασία δειγμάτων, οι διαδικασίες καθαρισμού και η ανάλυση μεγέθους σωματιδίων. Τα σύγχρονα φίλτρα κενού ενσωματώνουν επίσης χαρακτηριστικά ασφαλείας όπως βαλβίδες απελευθέρωσης κενού και μηχανισμούς προστασίας από υπερχείλιση, εξασφαλίζοντας την ασφάλεια του χειριστή και την ακεραιότητα των δειγμάτων κατά τη διάρκεια της λειτουργίας.