Mechanism of Syringe Filters in Streamlining Lab Processes

How syringe filters handle sample volumes efficiently

Syringe filters come in all sorts of sizes to handle different sample amounts, which really helps boost how much work gets done in labs. Labs love these because they work just as well on tiny samples as they do on big batches, and still keep everything filtered properly. What makes them stand out is how they use micro and ultra filtration techniques to get rid of particles in liquid samples. This stops those annoying clogs that plague older filtration systems. For researchers dealing with dozens of samples at once, getting clean results quickly matters a lot. Time saved here means experiments run smoother and data collection stays on track. Most modern labs have incorporated syringe filters into their standard protocols now, since they make day to day operations so much easier and give consistent results across multiple tests.

Reduced clogging risks for uninterrupted workflows

Syringe filters stand out because they're specifically designed to prevent clogging problems that plague many older filtration systems. Labs really appreciate how these filters keep things running smoothly without constant stoppages. What makes them work so well? The pore structure has been fine tuned over years of development to stay effective while reducing those annoying blockages that disrupt experiments. Some studies have found labs switching to syringe filters see around a 30% drop in equipment downtime. That means researchers spend less time waiting for filters to clear and more time actually conducting tests. For most lab managers, this translates into fewer headaches during busy periods when every minute counts toward meeting project deadlines.

Speed advantages over traditional filtration methods

Syringe filters give labs a real edge when it comes to speed since they let samples pass through much faster than regular filters do. Labs working under tight deadlines find this particularly valuable because it means getting results sooner rather than later. What makes these filters so effective is their simple construction that creates less blockage during the filtering process while still maintaining good analytical quality. Some studies show that switching to syringe filters can cut down sample processing time by around half compared to older techniques. While no one disputes the basic math here, what matters most is how this extra time frees up researchers to focus on other tasks or get those crucial findings out the door faster. That's why many modern labs have made syringe filters part of their standard equipment lineup.

The Role of Syringe Filters in Enhancing Analytical Accuracy

Particulate removal for contamination-free results

Syringe filters are really important for getting clean analytical results because they remove tiny particles that could mess up samples. The filters take out these little bits of stuff, which keeps the samples pure and trustworthy for testing purposes. In lab work, this kind of careful filtering matters a lot since even the tiniest impurities can throw off measurements and give wrong answers. Research shows that when labs use syringe filters, they get better data quality overall. This happens mainly because the filters cut down on background interference during chromatography tests, making it easier to spot what's actually in the sample without all the extra noise getting in the way.

Sterile filtration capabilities in sensitive applications

For labs working with delicate biological materials, getting rid of contaminants through sterile filtration matters a lot. Syringe filters that come with sterilizing grade membranes have become pretty much essential for this purpose. They knock out bacteria and other microbes, making lab work go smoother since researchers don't need to bother with complicated sterilization procedures anymore. Lab technicians will tell anyone that these filters make life easier, and there's actually research supporting this claim too. Studies show that when scientists use these special syringe filters during sample prep, they see fewer contamination issues compared to traditional methods.

Consistency in HPLC and GC sample preparation

Getting consistent samples ready matters a lot when running tests on High Performance Liquid Chromatography (HPLC) systems or Gas Chromatography (GC) equipment. Syringe filters help keep things steady during this process. These little devices stop the flow from jumping around too much, which means fewer weird variations showing up in test results. Most lab techs notice better repeatability when they incorporate syringe filters into their workflow for both HPLC and GC samples. The end result? More trustworthy data coming out of the instruments because everything starts off looking pretty much the same each time through the system.

Selecting Optimal Syringe Filter Materials for Specific Applications

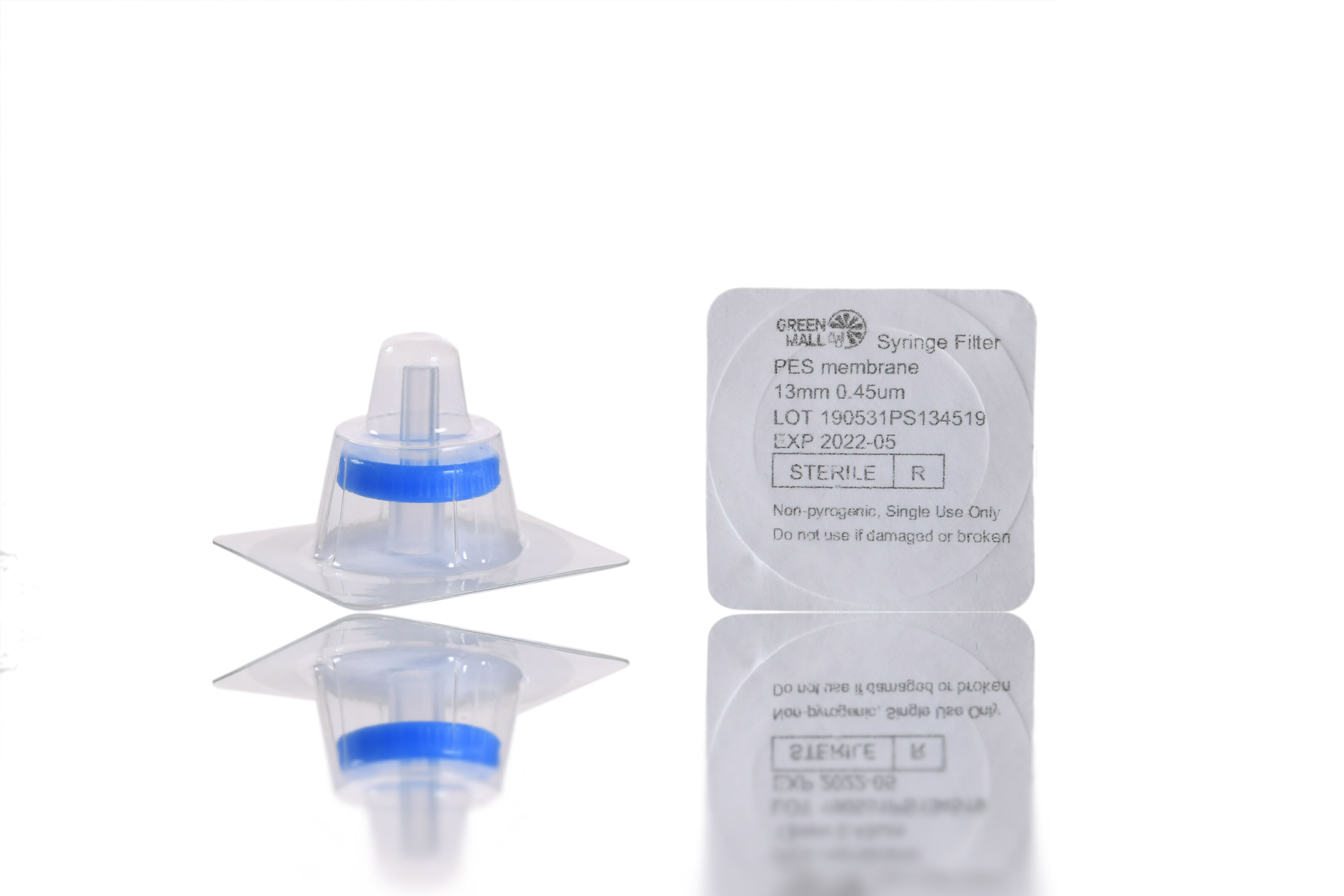

Chemical compatibility: Nylon vs PTFE vs PES membranes

Getting the membrane material right matters a lot for chemical compatibility, especially important stuff when working with syringe filters. Most labs go for nylon filters when dealing with water-based solutions because they work well across many chemicals and last longer than other options. For organic solvents though, PTFE membranes are usually better since they can handle harsh stuff like strong acids and bases without breaking down. Then there's PES or Polyethersulfone membranes that have pretty good chemical resistance too, so they show up in all sorts of lab situations where both water and some organic compounds might be present. Lab manuals always stress checking compatibility charts before selecting filters, something every technician learns after seeing what happens when incompatible materials meet. Taking time to match membranes properly not only saves money in the long run but also keeps experiments running smoothly without unexpected filter failures.

Low protein binding materials for biological samples

Keeping samples intact requires the use of low protein binding membranes during filtration of biological specimens. These special filters stop proteins and various biomolecules from sticking to their surfaces, something that helps labs avoid losing valuable samples or getting contaminated readings. Labs across the world have found through experience that low-binding materials make all the difference in getting accurate results from biochemical tests, especially important in drug development work where even tiny errors matter a lot. The right membranes just make sense for preserving what's in those samples, leading to consistent findings even when working under tough conditions in modern research facilities.

Solvent resistance requirements for organic solutions

When working with organic chemistry stuff, picking the right syringe filter really matters because solvent resistance determines if the filtration actually works. Good filters need to hold up against harsh solvents without breaking down or losing effectiveness. Otherwise, the whole filtration process gets compromised. Labs have strict tests for how well filters handle different solvents. Standards organizations like ASTM International run these tests so scientists know they can count on their equipment. The rigorous testing gives peace of mind when handling tricky solvent mixtures in the lab. Researchers spend hours trying to get accurate results, so knowing the filters won't fail during experiments makes all the difference. Without reliable filtration, even small contamination issues can throw off weeks worth of work.

Best Practices for Integrating Syringe Filters into Laboratory Workflows

Pre-filtration Strategies for High-Particulate Samples

Getting rid of big particles before they get to the main filter makes all the difference when dealing with samples full of debris that just love to clog things up. Lab techs often start with something like a bigger mesh filter or sieve first, catching those pesky large bits so they don't end up messing with the finer syringe filter downstream. This simple step not only saves money on replacement filters but keeps the whole system running smoothly without unexpected stoppages from blocked pathways. Most experienced researchers will tell anyone willing to listen that skipping this preliminary step leads to headaches later on when everything grinds to a halt because some stubborn particle decided it wanted to park itself permanently in the filter.

Pressure Control Techniques for Membrane Longevity

Syringe filters tend to last longer when proper pressure is applied during filtration since too much pressure often causes them to fail completely. Many labs now include pressure gauges in their equipment setup so they can keep track of what's happening during the process. This helps everything run smoother while making sure those expensive filters don't get damaged prematurely. According to most lab manuals out there, staying under the pressure limit specified by manufacturers does double duty it extends filter life AND keeps results reliable from batch to batch. Some technicians actually set their systems to stop automatically if pressure gets too high, just as an extra precaution against accidents or mistakes.

Single-Use Protocols to Prevent Cross-Contamination

Single use syringe filters have become standard equipment in most labs where sample contamination remains a big problem. By getting rid of the need to clean and reuse filters, these disposable options cut down on potential errors during experiments. Labs that switched to this approach report fewer issues with contaminated results. Research from several institutions shows contamination rates drop by around 40% when using disposables instead of traditional methods. For researchers who deal with sensitive biological materials daily, this improvement makes all the difference in producing trustworthy data for publications and regulatory submissions.

Application-Specific Considerations for Maximum Efficiency

Environmental testing protocols using syringe filters

Syringe filters are essential tools for getting accurate readings when testing water samples in environmental studies. They help quantify contaminants properly because they're built with special membranes that trap pollutants while still letting researchers analyze what's left behind. Labs need to stick with certified filters since most environmental regulations demand this kind of equipment for valid results. When labs invest in good quality filters, they save time on repeat tests and maintain trust in their findings. After all, nobody wants to base policy decisions on faulty data from cheap or improper filtration methods.

Pharmaceutical QC workflows requiring 0.22µm sterilization

In pharmaceutical quality control work, syringe filters with 0.22 micrometer pores play a vital role, especially when preparing samples for testing. These tiny filters act as barriers against microbes during processing, keeping everything clean throughout the QC process. Industry professionals consistently point out that following proper sterilization steps with these filters makes a real difference in product reliability, which directly affects both effectiveness and patient safety. Most labs have adopted this approach as standard operating procedure rather than optional extra. The pharmaceutical sector relies heavily on such filtration methods to maintain consistent quality standards across different production batches and testing scenarios.

Balancing throughput and precision in clinical diagnostics

In clinical diagnostics, syringe filters play a really important role when labs need to handle lots of samples but still get precise results. These filters let technicians process patient samples quickly without losing the accuracy needed for proper diagnosis. Research shows time and again that good filtering makes all the difference in test quality. Labs that use syringe filters regularly report faster turnaround times while keeping their diagnostic accuracy rates high. This means doctors get reliable information sooner, which leads to better treatment decisions for patients. The whole healthcare system benefits from this efficiency boost in diagnostic work.

FAQs about Syringe Filters

What are syringe filters used for?

Syringe filters are used primarily to remove particulates from liquids in laboratory settings. They are essential for ensuring sample purity, reducing contamination risks, and enhancing analytical accuracy in various applications such as chromatography analyses.

How do syringe filters minimize clogging?

Syringe filters are designed with optimized pore structures that allow efficient filtration while minimizing the risk of blockages. This design maintains smooth workflows and reduces downtime in laboratory processes.

What materials are syringe filters made of?

Syringe filters are made from various materials, including Nylon, PTFE, and PES membranes. These materials offer different chemical compatibilities and are chosen based on the specific requirements of sample filtration.

Table of Contents

- Mechanism of Syringe Filters in Streamlining Lab Processes

- The Role of Syringe Filters in Enhancing Analytical Accuracy

- Selecting Optimal Syringe Filter Materials for Specific Applications

- Best Practices for Integrating Syringe Filters into Laboratory Workflows

- Application-Specific Considerations for Maximum Efficiency

- FAQs about Syringe Filters